MiniPat Vertical Carousel

Carriers (shelves) are connected to transport chains that rotate the entire stored inventory around inside a steel clad casing in either direction working on the shortest routing principle to deliver the requested items at an ergonomic height to the operator.

The carriers are presented at the access port in front of the operator at a picking / placing height, usually 900mm, depending on the pitch of the carriers.

Intermediate carrier levels can be installed at any time to cater for small parts in bins etc. Multiple levels can be configured to meet the desired volume criteria.

The picking port working area is illuminated by directional low voltage LED

Schwab Tower Heavy Duty Lift

Schwab Tower is a vertical Lift capable of storing a wide variety of products such as steel or aluminium sheet and profiles, tooling, jigs, large, heavy and "ugly" parts etc. The Tower cassette can support a load of up to 5,000Kg each with variable size possibilities up to 12,000mm wide by 2,000mm depth with machine heights up to 16 metres.

The Tower crane can also be designed to travel laterally where such a configuration makes better use of the available floor space.

Unlike conventional vertical lift systems a Tower can also be configured in a multi stack version.

This has the benefit of accommodating a larger number of trays where required whilst still operating with one lift mechanism.

Schwab Multi-loop Paternosters

Steel carriers are connected to transport chains that rotate the entire complement of carriers around inside a framework in either direction working on the shortest routing path principle.

The required carrier is presented at the access port in front of the operator at an ergonomic working height.

Goods presentation can be brought forward of the framework to a loading nose arrangement allowing free access for manual picking or by Fork Lift Truck, Overhead Crane etc.

Products can be delivered to the front, rear or both, mezzanine floor and basement levels or in any combination of these.

Aids to greater efficiency

Being able to make the most efficient use of your space is only part of the solution to effective stock handling. It is also vitally important that you are able to locate and retrieve stock in a timely manner.

Additional equipment such as barcode readers and printers can greatly simplify the identification of stock to prevent miss-picks and similar errors. But this is only part of the solution...

Even greater savings can be made by using 'Batch Picking' where a number of orders are satisfied in parallel guided by 'Put to Light' indicators against the receiving bins.

Other Storage Systems

As part of our overall product portfolio and to provide our clients with the complete solution (new stores or warehouses will rarely use only automated storage) we also provide a comprehensive range of conventional storage and handling systems to complete the full requirement.

We can provide pallet racking to suit any application, from wide aisle, narrow aisle to mobiles, the right systems are chosen to meet storage and space criteria.

It's all supplied and installed to the latest standards to ensure that your staff and stock enjoy a happy and safe coexistence.

Vertical Carousel

Storage and picking for a wide range of small to medium size items

Space saving goods to man picking system with definable sizing, configured to suit the space

Minimise bending and stretching, eliminate climbing completely

A series of carriers (shelves) are rotated around inside a steel casing in either direction by the shortest routing principle, to present the reuested items to an operator working at an ergonomic and comfortable position, picking is faster as walking is minimal compared to using shelving.

Carriers (shelves) can be configured to hold almost any variety of bins, totes, containers or using adjustable dividers for cartons, each is presented in seconds at the access port which has a table at the front to help sort picks and replenishments quickly.

illuminated by low voltage lighting.

A Light Bar location system provides a visual and quick identification of the requested part positions along the carrier reducing search time and provide accurate picking and replenishment reducing the possibilities of miss-picks.

Carousels can be supplied in the most effective dimension to fit into a given area to make the maximum use of floor space, between columns and other structures or machinery or simply to meet the number and volume of items to be stored.

Complete with object light curtains preventing machine rotation if an item is not returned correctly or anything is protruding. Automatic doors also have personnel protection fitted.

Small footprint with high density storage

DRIVE SYSTEM

Practical, safe, secure and engineered for quality, Vertical Carousels have transport chains and drive chains with at least a 7:1 brake load ratio for the most arduous tasks and conditions.

CONFIGURABLE SIZE

There are size options available, the picture Here shows carriers of 3,000mm wide and 600mm deep, storing small to medium sized Items; installed under a mezzanine floor and maximising the available headroom.

Controlled by a simple keypad operating In a stand alone mode.

Single or multiple access ports, on the same or opposite sides of the unit, provide more lexible picking from both ground and mezzanine floor levels or on opposite sides of the machine.

A worktable at the access port provides a convenient area for sorting and counting items.

Intermediate carrier levels can be installed at any time to cater for small parts in bins etc. Multiple levels can be configured to meet the desired volume criteria. Flexible configuration allows for single storage levels tier and mixed pitch to cater for all sizes of bins and totes, cartons, etc.

Electro magnetic secured doors for limiting access, 1 tier and 2 tiers totes, 2 and 3 Tier bins, Drawers, Dividers.

Single and 2 tier level tote bins

2 & 3 tier level small parts bins

Adjustable carrier dividers

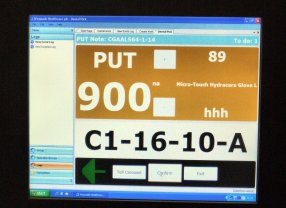

CONTROL

Control options include a simple call for a specific carrier to a keypad with inventory management for stand alone operations to touch screen PC?s integrated with MRP/ERP systems and WMS.

Computer control for stand alone and network integration, weighing scales, bar code readers, printing for labels and reports along with batch picking using pick and put to light technology, weigh scales and other accessories make up a comprehensive package for efficient operational stores.

Standard and bespoke software can be provided to achieve the client?s criteria; we can also manage non carousel stored parts.

Carousels can be heated or refrigerated.