MiniPat Vertical Carousel

Carriers (shelves) are connected to transport chains that rotate the entire stored inventory around inside a steel clad casing in either direction working on the shortest routing principle to deliver the requested items at an ergonomic height to the operator.

The carriers are presented at the access port in front of the operator at a picking / placing height, usually 900mm, depending on the pitch of the carriers.

Intermediate carrier levels can be installed at any time to cater for small parts in bins etc. Multiple levels can be configured to meet the desired volume criteria.

The picking port working area is illuminated by directional low voltage LED

Schwab Tower Heavy Duty Lift

Schwab Tower is a vertical Lift capable of storing a wide variety of products such as steel or aluminium sheet and profiles, tooling, jigs, large, heavy and "ugly" parts etc. The Tower cassette can support a load of up to 5,000Kg each with variable size possibilities up to 12,000mm wide by 2,000mm depth with machine heights up to 16 metres.

The Tower crane can also be designed to travel laterally where such a configuration makes better use of the available floor space.

Unlike conventional vertical lift systems a Tower can also be configured in a multi stack version.

This has the benefit of accommodating a larger number of trays where required whilst still operating with one lift mechanism.

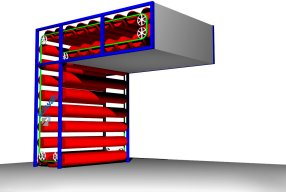

Schwab Multi-loop Paternosters

Steel carriers are connected to transport chains that rotate the entire complement of carriers around inside a framework in either direction working on the shortest routing path principle.

The required carrier is presented at the access port in front of the operator at an ergonomic working height.

Goods presentation can be brought forward of the framework to a loading nose arrangement allowing free access for manual picking or by Fork Lift Truck, Overhead Crane etc.

Products can be delivered to the front, rear or both, mezzanine floor and basement levels or in any combination of these.

Aids to greater efficiency

Being able to make the most efficient use of your space is only part of the solution to effective stock handling. It is also vitally important that you are able to locate and retrieve stock in a timely manner.

Additional equipment such as barcode readers and printers can greatly simplify the identification of stock to prevent miss-picks and similar errors. But this is only part of the solution...

Even greater savings can be made by using 'Batch Picking' where a number of orders are satisfied in parallel guided by 'Put to Light' indicators against the receiving bins.

Other Storage Systems

As part of our overall product portfolio and to provide our clients with the complete solution (new stores or warehouses will rarely use only automated storage) we also provide a comprehensive range of conventional storage and handling systems to complete the full requirement.

We can provide pallet racking to suit any application, from wide aisle, narrow aisle to mobiles, the right systems are chosen to meet storage and space criteria.

It's all supplied and installed to the latest standards to ensure that your staff and stock enjoy a happy and safe coexistence.

Paternosters

Storage and Handling for a wide range of products including Rolls, Reels, Cylinders, and Long goods

Space saving designs of goods to man system with definable sizing configured to suit the available space in single and multi loop format

Steel carriers are connected to transport chains that rotate the entire complement of carriers around inside a framework in either direction working on the shortest routing path principle.

The required carrier is presented at the access port in front of the operator at an ergonomic working height, Goods presentation can be brought forward of the framework to a loading nose arrangement - as illustrated above - allowing free access for manual picking or by Forklift Truck, Over head Crane etc.

Products can be delivered to the front, rear or both, mezzanine floor and basement levels or in any combination of these.

The outer sides of the unit is protected with steel or composite sheet cladding as required for safety to prevent access to any moving part, a light curtain is installed at the front of every access port for operator safety.

Paternosters are manufactured to store and handle products such as - though not limited to - Rolls, Reels, Cylinders, Bar, Tube, Clothing and, Tyres.

Machines sizes are designed to suit individual criteria and requirements for product dimensions, quantity, and weight, whilst there are limits to these the system flexibility and versatility can accommodate the majority of client requests.

The above illustration demonstrates the complete versatility of the multi-loop paternoster system, product types can be mixed together in one unit, bar, tooling, finished goods, cable reels, etc. etc. The machine is equipped with a loading nose for ease of movement in and out without obstructions; the access zone is protected by a photoelectric curtain from ground to 1500mm high. Manufactured to store and handle heavy weight products whether they are long, round, square or awkward shapes, Schwab can store it, the number of loops is determined by the storage volume and weight loadings required.DIMENSIONAL DATA

Height: 25M, and more

Depth: 30M, and more

Width: 8M, and more

Load: Up to 1,600Kg per mandrel and much more on beam supported systems

Total loads can be many thousands of kilograms with frame configurations from 1 to 150, if you have a specific requirement, please ask us for a solution.

CABLE REELS

Cable reels can be stored individually allowing the cable to be cut to length in situ; use of mechanical handling equipment, or can be stored side by side on a two beam configuration and 2 reels in the depth on 4 beam arrangement for smaller reels.

MEASURING

Allowing the user to take a required cable length directly from an individual reel without unloading the reel from the paternoster, time-saving and convenient.

The measuring gauge can be fixed to a sliding column to move the device from reel to reel or can be trolley mounted. Dial in the required length, press start and when the target is reached the gauge stops unwinding.

We can provide a reel to reel winding / unwinding and coiling systems, in either a manual or a powered version.

LONG GOODS

Steel Bar is stored on a carrier with a grid of welded upright steel sections to prevent movement out of the storage level whilst allowing access to the products by forklift truck or overhead crane using a "loading nose" to present the carrier free of overhead obstructions.

The ends of the carriers are closed with steel plates to hold the bars in place laterally, it?s possible also to have these ends with a system with fitted safety light barrier s in the outer cladding material, so that bar can be moved lengthways out of the machine directly to a work station.

Welded steel sections to retain the stock securely

Enclosed end plates; preventing lateral stock movement

Easy access for forklifts

Loading nose for obstruction free access by overhead crane

carrier to a conveyor from the side

CYLINDERS

cylinders with a loading

nose for access by an

overhead crane.

Cylinders can be stored in various ways-

on V blocks

Suspended from chains & beams

On beams

Storage can on individual levels or a number of cylinders per level in a single or multiple loop machine.

Roll products suspended

individually from a beam

ROLLS

The versatile paternoster can store many and varied products with individual storage level designs to suit the product profiles and handling requirements.

A multi loop paternoster with 2 frames accommodate rolls up to 6.0M long on support arms to retain the load and permit loading with a forklift or crane.

Rolls can be stored on mandrels, in enclosed carriers or loose but restrained to prevent movement.

Machines with cutting table - also supplied in the range - store cloth rolls on a mandrel through the centre core.

The powered cutting table is fitted with a measuring gauge programmable in 1cm increments.

Cloth is inserted between rollers on the table and automatically pulled through to the required length and cut using a captive electric knife.

Carpet and Vinyl roll up to 5.0M wide x 700mm diameter.

2 rolls can be stored side by side, such as 1 x 3m and 1 x 2M.

CONFIGURATION

The physical shape configuration of the paternoster is so variable that it can be manufactured to fit into virtually any shape and area available for use; including multiple loops, more than one access ports, etc. these are just a few of the possibilities :-

Four frame system with a loading nose and, a Jib Crane; for handling the goods.

Multi Loop paternosters can extend to 30M, or more into the warehouse.

They can also be configured to store different products types in the same unit, for example long goods and reels plus a pitch difference between levels to cater for taller items.

The shape can also follow the line of a sloping roof, span building to building and so on.

Free up valuable floor space and utilise the height of the area, entry / exit ports can be positioned at any point to suit the positioning of production machines or support columns.

The machine profile can be manufactured to suit the space available

"T" bridge unit, or "L" or "U" profiles

Bridge unit with one or more entry / exit ports, to deliver product where it?s required in the building, other than the entry / exit ports all storage held above the floor level to leave space for manufacturing underneath the structure.

With an ability to determine the shape to meet the area available very little remains an unusable space normally left unused.

Machines can be enclosed with steel cladding for dust reduction or, refrigerated with insulated panels or heated within the structure.

Access port doors can also be fitted for security.

Other possibilities include:

Machine with goods-in access installed on the outside of a building with delivery of replenishment stock loaded directly off the vehicle and the machine accessed inside the building feeding to production.

CONTROLS

The base controller is a manual up and down button operation to bring the required storage level to the access port, by the shortest route.

More advanced control is achieved with a keypad

We can also provide network linked control through a PC with inventory Management Software, Reports, Printing, etc.

PC and machine controller, Bar Coding, Security systems, access by department and user and numerous other features as available.